Technology Overview

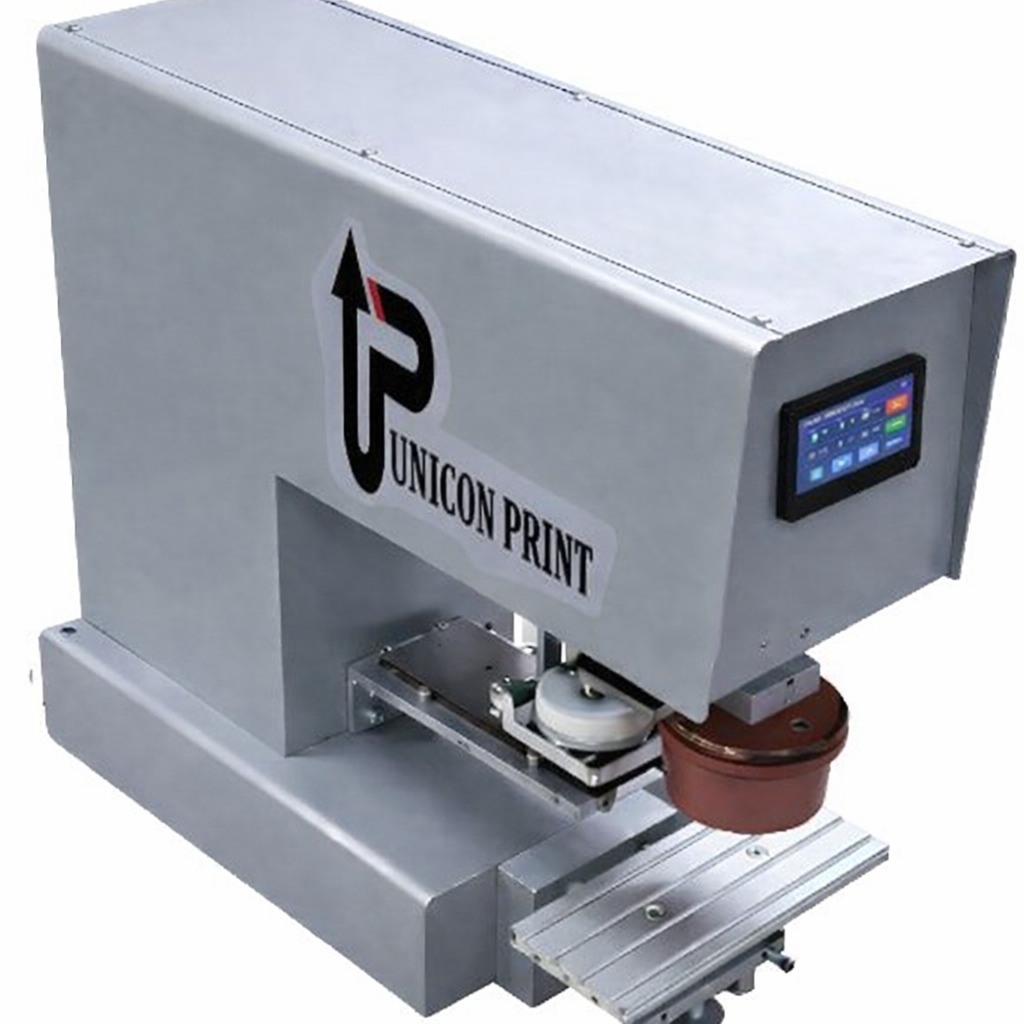

Pad printing machines are specialized industrial printing systems designed to transfer inked images onto objects with irregular, curved, textured, or recessed surfaces. Unlike conventional printing methods, pad printing uses a soft silicone pad to pick up ink from an etched plate and precisely deposit it onto the product surface. This makes the technology ideal for printing on complex shapes where flat printing methods are not feasible.

Applications & Material Compatibility

These machines are widely used across industries such as automotive, electronics, medical devices, cosmetics, promotional products, household appliances, and industrial components. Pad printing machines can print high-resolution logos, text, symbols, and functional markings on materials including plastics, metals, glass, rubber, ceramics, and coated surfaces. The process ensures excellent ink adhesion, sharp image definition, and consistent repeatability even at high production speeds.

Machine Configurations & Automation Features

Modern pad printing machines are available in manual, semi-automatic, and fully automatic configurations, allowing businesses to choose solutions that match their production scale and automation needs. Advanced models are equipped with PLC controls, touch-screen HMIs, servo-driven movements, and multi-color printing capabilities, enabling precise control, reduced setup time, and higher productivity. Custom jigs and fixtures further enhance accuracy and ensure uniform printing on every part.

Performance Benefits & Operational Advantages

With their compact design, low ink consumption, high efficiency, and long operational life, pad printing machines offer a cost-effective and reliable printing solution. They are especially valued for their flexibility, allowing quick changeovers between jobs and compatibility with a wide range of specialty inks such as UV, solvent-based, and two-component inks. This makes pad printing machines an essential choice for manufacturers seeking durability, precision, and visual excellence in product marking and decoration.